Brant & Cochran was founded in 2015, and they make heirloom quality, Maine wedge pattern axes by hand in their South Portland shop.

They take tool steel, apply heat, pressure and skill and make an axe that Field & Stream Magazine calls one of the four best in the world.

Updated 10/23/2024

Construction

Medium carbon tool steel billets are shaped by hydraulic press, power hammer, and hammer and anvil, then rough forged to make the bit of the axe.

Heat treated at 1525 degrees, then tempered at 450 degrees, giving the entire axe head a Rockwell hardness of 56 to 58.

After heat treatment, the axe head goes back to the grinder to give it approximately a 22-degree angle at the bit, similar to that found on traditional Maine wedge pattern axes.

Brant & Cochran hafts in the traditional way, starting with an Amish-turned hickory handle of their design, they shape it to fit the eye using rasps, draw knives, spoke shaves, razor knives, and sandpaper.

Once the axe is fully assembled, the handle is rubbed with two coats of boiled linseed oil over two days to condition it.

The Forester

The Forester The Scout

The Scout The Fireside Splitter

The Fireside Splitter

The Foresters Friend

The Foresters Friend Dirigo Belt Axe

Dirigo Belt Axe Acadian 1/2 Wedge Axe

Acadian 1/2 Wedge Axe

2 lb Hudson Bay Camp

2 lb Hudson Bay Camp 2.25 lb Boy's Axe

2.25 lb Boy's Axe 3.5 lb Michigan Double Bit

3.5 lb Michigan Double Bit 3.5 lb Dayton SB

3.5 lb Dayton SB 3.5 lb Jersey Classic

3.5 lb Jersey Classic 5 lb Fallers SB

5 lb Fallers SB 5 lb SB Splitting

5 lb SB Splitting 6 lb Flathead

6 lb Flathead 7 lb Maul

7 lb Maul

Fireside Friend Splitting

Fireside Friend Splitting Sportsman's (Leather)

Sportsman's (Leather) Campers (Std)

Campers (Std) Campers (Long Handle)

Campers (Long Handle) Black Eagle Double

Black Eagle Double Hunters

Hunters

Flathead

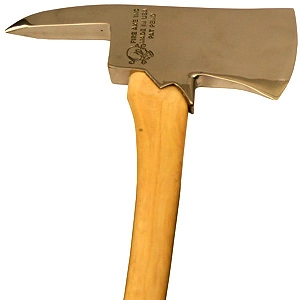

Flathead Pickhead

Pickhead

Ultra-Force Axes

Ultra-Force Axes Flat Head Axes

Flat Head Axes Pick Axes

Pick Axes

Razor Series

Razor Series Proline Series

Proline Series Chopping Axe Series

Chopping Axe Series

Woodman's Pal

Woodman's Pal

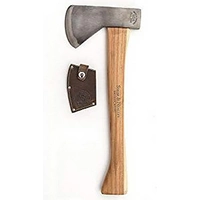

Hudson Bay

Hudson Bay Penobscot Bay

Penobscot Bay Outdoorsman’s Belt Axe

Outdoorsman’s Belt Axe

Steel Handle Camp

Steel Handle Camp Sportsman Camp

Sportsman Camp Hickory Handle Camp

Hickory Handle Camp

The Canoe

The Canoe The Trekker

The Trekker Large Double Bit

Large Double Bit Any brands marked with a gold star shows that at least one product, or all of that companies products are made in the USA using virtually 100% domestic sourced materials & labor.

Any brands marked with a gold star shows that at least one product, or all of that companies products are made in the USA using virtually 100% domestic sourced materials & labor. A silver star shows their products are assembled and/or machined in America using domestic labor and a mix (of any proportion) of both domestic and imported materials.

A silver star shows their products are assembled and/or machined in America using domestic labor and a mix (of any proportion) of both domestic and imported materials. A bronze star shows that their products are assembled in the U.S. using all imported parts.

A bronze star shows that their products are assembled in the U.S. using all imported parts. An 'empty star' indicates that the product is designed or engineered in the US, and/or some of the parts have been produced here, but are sent elsewhere to be assembled into a final product.

An 'empty star' indicates that the product is designed or engineered in the US, and/or some of the parts have been produced here, but are sent elsewhere to be assembled into a final product.